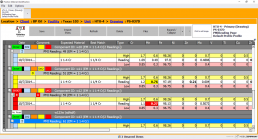

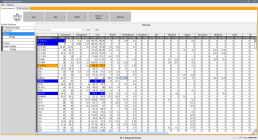

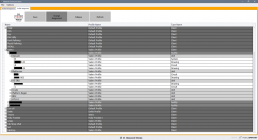

With Touch Mobile’s software for Positive Material Identification, NDT professionals in the field can instantly apply quality control to multiple shots collected on PMI guns across multiple PMI Techs (see image #1 below). They can then immediately generate a re-shoot report within seconds of synchronizing their PMI gun’s shot data into their PC tablet. Due to our complete Material and Chemistry Library tool (see image #2 below), and our ability to easily apply multiple unique chemistry profiles to individual circuits, systems, line numbers and drawings (see image #3 below) the PMI data is instantly compared to all known alloys (and even custom ones you may wish to include). The system then compares all PMI chemistry data from the shots to the library’s known material profiles and clearly displays any variations between the expected and actual data.

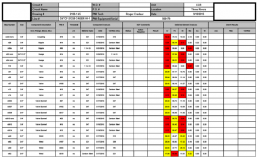

Each component that has an element in its chemistry whose percentage is lower than expected is highlighted in red, Each component that has an element in its chemistry whose percentage is higher than expected is highlighted in yellow. All remaining elements found to be within the library’s metal specifications are not highlighted (see image #4 below). It is this instantaneous quality control capability that makes the immediate re-shoot reports possible and ensures that no time is wasted determining the nature of the material being inspected. This keeps your PMI projects moving forward at record speed.

Ultimately, all readings from multiple simultaneous PMI teams have their data encrypted and securely transmitted to a central database for reporting (see images #4 and #5 below). The hours and dollars saved by our automated PMI data quality control capabilities and our readily-available and actionable reporting cannot be understated.

or

Click these links to review our other NDT applications, such as:

CUI Moisture Detection

Thickness Measurements

Visual & API Inspections