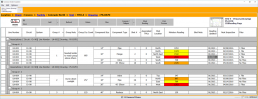

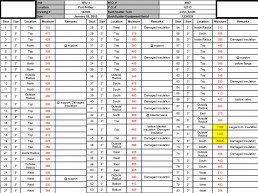

Using Touch Mobile·NDT’s application for CUI moisture detection, in combination with Neutron Backscatter Moisture Detectors built specifically for the petrochemical industry, NDT professionals are finally able to quickly and accurately record, organize and analyze relative moisture levels across entire units and facilities. Components of a unit can even be grouped on-the-fly by the CUI technician right on the tech’s intrinsically safe PC tablet and the relative moisture results of those groups are instantaneously and clearly displayed (see image #1 below). The system can work for hours disconnected from the network without preventing your technicians from completing their work. However, as soon as a connection is established, the system automatically synchronizes with a server and accurate results are instantly available for full and actionable reporting (see image #2 below). Our software saves both time and money so that NDT professionals can move from area to area throughout a facility while management can see the actionable data in near real-time.

or

Click these links to review our other NDT applications, such as:

Positive Material Identification

Thickness Measurements

Visual & API Inspections

CUI Moisture Detection is used as an NDT broadbrush technique on any working component within a facility to scan for possible corrosion. Neutron backscatter moisture detectors sweep from area to area, easily reaching any component (see images below). CUI Moisture Detection uses neutron feedback in order to determine moisture levels. Our software takes this information and instantly makes side-by-side comparisons between relative moisture levels. Our solution provides expert analysis of this data, and actionable reporting output clearly highlights the largest variations in moisture levels. These results are displayed instantaneously on an intrinsically safe PC tablet. Instead of taking months to interpret this relative data with the need to re-shoot only surfacing much later, comparison between relative moisture levels between areas is available on-site and ready for immediate reporting. Once relative moisture levels are analyzed by our CUI Moisture Detection software, quality control teams may re-collect data immediately, if necessary, with actionable data for NDT professionals.